A modular building platform for the most ingenious of robots

Playground of new possibilities arises in constructing miniature soft-bodied machines

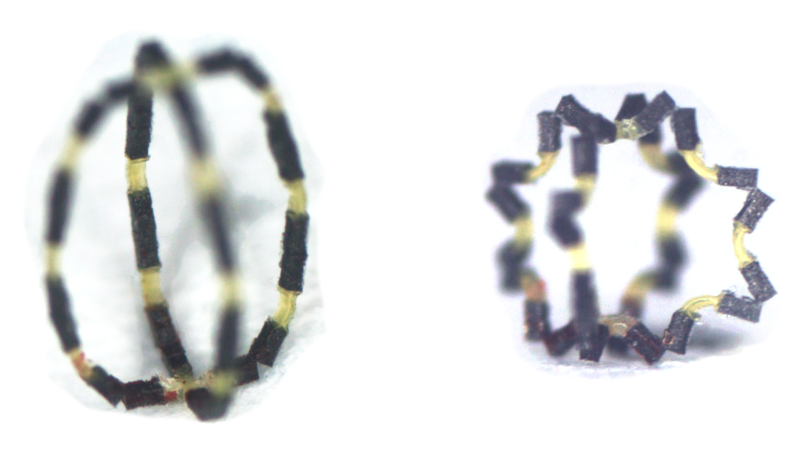

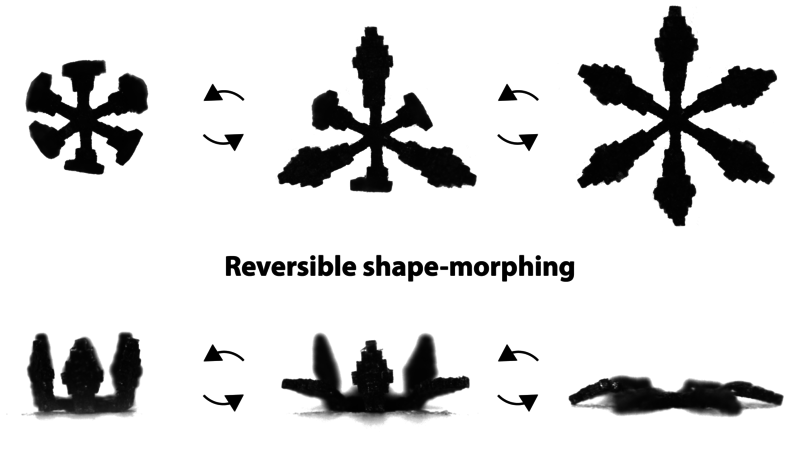

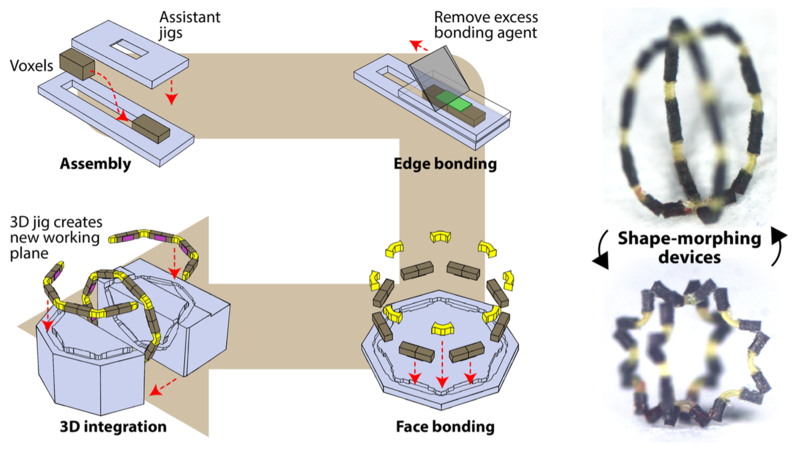

As one would do with a Lego system, the scientists can randomly combine individual components. The building blocks or voxels – which could be described as 3D pixels – are made of different materials: from basic matrix materials that hold up the construction to magnetic components enabling the control of the soft machine. “You can put the individual soft parts together in any way you wish, with no limitations on what you can achieve. In this way, each robot has an individual magnetisation profile,” says Jiachen Zhang. Together with Ziyu Ren and Wenqi Hu he is first author of the paper entitled “Voxelated three-dimensional miniature magnetic soft machines via multimaterial heterogeneous assembly”. The paper was published in Science Robotics on April 28, 2021.

The project is the result of many previous projects conducted in the Physical Intelligence Department at MPI-IS. For many years, scientists there have been working on magnetically controlled robots for wireless medical device applications at the small scale, from millimeters down to micrometers size. While the state-of-the-art designs they have developed to date have attracted attention around the world, they were limited by the single material with which they were made, which constrained their functionality.

“When building soft-bodied miniature robots, we have many different and often complex designs. As a result of their small size, the available fabrication capability is very limited, and this poses a major challenge. For years, researchers have been trying to develop an innovative fabrication platform that provides scientists with completely new capabilities. Our team has now succeeded in demonstrating a new way to construct much more complex soft robots with different components rather than just one. By mixing and matching, we enable tailor-made functionalities and complex robot morphologies. Our new modular building platform will pave the way for many new functional wireless robots, some of which could potentially become the minimally-invasive medical devices of the future,” says Metin Sitti, who leads the Physical Intelligence Department and has pioneered many wireless medical and bio-inspired miniature robots.

“We have seen 3-D printing or mold casting of voxels with only one material. That limits the functionality – a single material can only do so many things,” says Ziyu Ren. “If you want more functionality like we did and a unique magnetisation profile, you have to introduce a whole set of different materials, for instance by mixing various non-magnetic and magnetic materials.

“Previously, each robot’s magnetisation profile was limited to certain patterns due to the strong coupling with the geometry of the robot. Now, we have created a platform that can achieve a flexible magnetisation profile. We can do so by freely integrating multiple magnetic parts together in one system,” Jiachen Zhang adds.

The new building platform enables many new designs and is an important milestone in the research field of soft robotics. The Physical Intelligence Department has already developed a wide variety of robots, from a crawling and rolling caterpillar-inspired robot, a spider-like construct that can jump high, to a robotic grasshopper leg and magnetically-controlled machines that swim as gracefully as jellyfish. The new platform will accelerate the momentum and open up a world of new possibilities to construct even more state-of-the-art miniature soft-bodied machines.

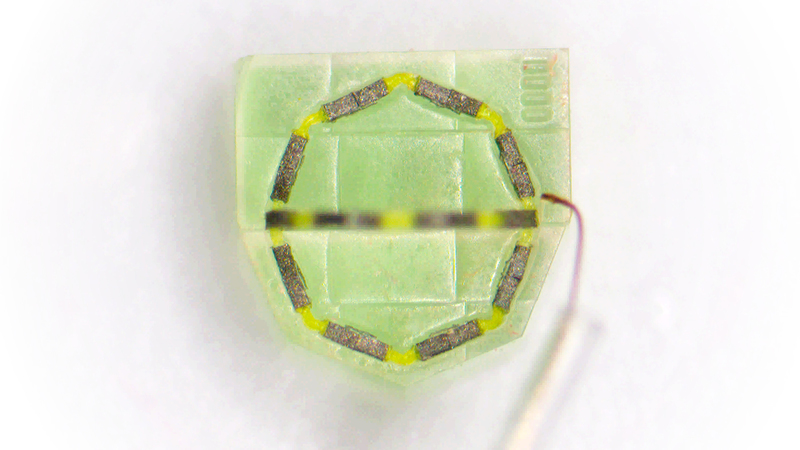

The scientists base each construction on two material categories. The base is mainly a polymer that holds up the matrix. But also other kinds of soft elastomers, including biocompatible materials like gelatin, are used. The second category comprises materials embedded with magnetic micro- or nanoparticles that make the robot controllable and responsive to a magnetic field.

Thousands of voxels are fabricated in one step. Like dough being distributed in a cookie tray, the scientists use tiny mold casts to create the individual blocks – each of which is no longer than around 100 micrometers. The composition then happens manually under a microscope, as automating the process of putting the particles together is still too complex. While the team integrated simulation before building a robot, they took a trial and error approach to the design until they achieved perfection. Ultimately, however, the team aims for automation; only then can they reap the economies of scale should they commercialize the robots in the future. “In our work, automated fabrication will become a high priority,” Jiachen Zhang says. “As for the robot designs we do today, we rely on our intuition based on extensive experience working with different materials and soft robots."

Video

Related Articles